water softeners & hardness detection

Why monitor hardness?

Hard water is a global problem. Consumers can and do benefit from using soft water because softening reduces detergent usage in both household and industrial settings. In addition, softening reduces scale buildup on heat transfer surfaces that can lead to increased energy consumption and premature failure of water heaters and boilers. In spite of their benefits, conventional water softeners have a drawback—they require salt for regeneration. Current softeners use excessive amounts of salt, which typically is released into municipal sewer systems and ultimately into rivers and water systems. In some cases, water softeners are banned by communities, or their use is restricted by requiring high-efficiency systems.

improving softener operation & efficiency

Atlas Hardness Sensors

Atlas Hardness Sensors

Atlas Hardness Sensors

Benefits of real-time hardness detection

- Initiate regeneration based on hardness breakthrough

- Monitor softener operations (including regeneration)

- Identify & report problems

The Atlas sensors can be installed on the water pipe leaving a water softener. As the water softener’s resin is exhausted, calcium will begin to appear in the softened water. The Atlas sensor is able to detect the initial breakthrough of calcium and will send a signal to the softener control valve system indicating regeneration is needed.

Sensor Products

Atlas Hardness Sensors

Atlas Hardness Sensors

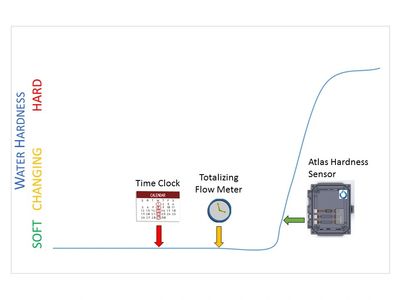

The hardness sensor in development will allow the greatest savings in salt and water during regeneration because the sensor is capable of detecting the exact time that regeneration is needed.

Residential model:

We envision utilizing a fixed set point for sending a signal to regenerate the water softener.

Industrial & Commercial models:

Industrial water treatment involves more flexibility in regeneration timing. The industrial hardness sensor is capable of relaying the relative amount of hardness detected and will allow for high flexibility of regeneration timing by advanced controls.

Water Softener Operation with Sensors

Atlas enables reliable & efficient operation

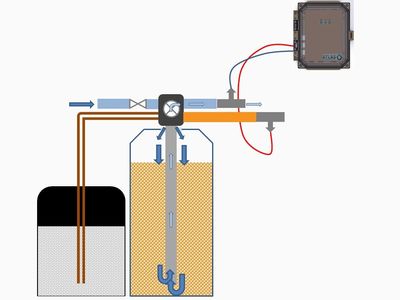

Water softeners are comprised of three main components: a resin tank, a brine tank, and a regeneration control system. Hard water, which contains ions of dissolved calcium, passes through a tank filled with resin beads. These beads have sodium ions that are exchanged for calcium and produce soft water until the resin is saturated with calcium. At this point, low levels of calcium will be present and the hardness sensor will send a signal indicating regeneration is required. The resin is regenerated by drawing a brine solution from the brine tank into the resin tank to displace the minerals in the resin and recharge the resin with sodium ions. A high concentration of salt is needed for regeneration to overcome the strong binding of hardness (e.g. calcium and magnesium) ions to the resin. Tap water is used to displace and rinse the brine from the resin. A waste stream containing a mixture of salt and minerals removed during the original softening process is sent to a drain for disposal.

Installation of an Atlas hardness sensor on a softener will substantially reduce salt and water consumption (and waste flows). Another benefit of measuring the actual hardness level in the product water is that our direct-detection method allows for variability of incoming water quality.

Copyright © 2024 Atlas Sensor Technologies, inc. - All Rights Reserved.

Powered by GoDaddy